1

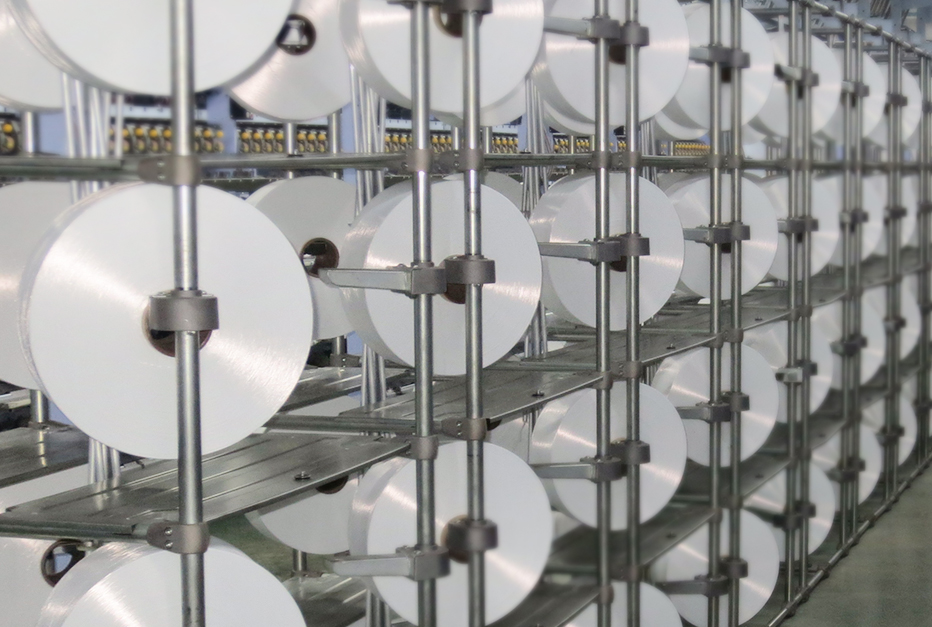

The PA6 chips are filled into the melt line and gradually liquefied by heating strips. The melting granules is finally passed through the high mechanical pressure of the screw to the spinning head and pressed through it.

2

Spinning pumps press the polymer melt through micro-fine spinnerets under extremely high pressure. The nylon filaments created are then bundled into yarns, drawn over godets and wound using a winder.

3

Pre-oriented yarns (POY) are the starting material for a wide range of fashion, sports, functional and home textiles. It is mainly used in texturizing to make textured yarn and can also be used in draw warping for weaving and warp knitting of fabrics. Here in JIAYI we following texture the POY into DTY(Draw Textured Yarn) form.

4

The eFK is a highly efficient DTY machine with the latest godet feed technology and benefits for best nylon yarn quality.Texturing is a finishing step that transforms the POY supply yarn into DTY and hence into an attractive and unique product.During texturing, pre-oriented yarn (POY) is permanently crimped using friction. As a result, elasticity and heat retention are increased; the nylon yarn receives a pleasant handle, while thermal conduction is simultaneously reduced.

5

At every stage of production is a stringent check before the subsequent process;

From polymers there is an IV, moisture content percentage and end group analysis.

For POY, there is a thorough check of deniers and filaments.

In the texturing process, the POY grade, luster, BS, E% and tenacity go through rigid tests.

In the twisting process the checks are for package hardness, package size and twist direction.

Finally, for DTY checking,we test the physical properties, such as dying ability, tenacity,oil content,evenness, elongation,crimp contraction, boiling water shrinkage...